Limit Testing

Test component substance to defined limit

Limit Testing of Pharmaceutical Waters & Utilities

Beyond Purified Water (PW) and Water for Injection (WFI), many pharmaceutical operations require tailored testing of various water streams—such as feed water, pre-treatment, RO/EDI product, condensate, and rinse waters—against user-defined acceptance limits.

When Is Limit Testing Required?

- Qualification and monitoring of pre-treatment and intermediate waters

- Clean steam and condensate quality checks (for sterilisation and humidification)

- Final rinse waters in cleaning validation

- Potable water assessment against WHO/EU guidelines

- Troubleshooting excursions and CAPA investigations

Chemistry Tests You Can Trust

- Conductivity, pH, alkalinity, and total dissolved solids (TDS)

- Total Organic Carbon (TOC)

- Anions: chloride, sulphate, nitrate, nitrite, phosphate, silicate

- Metals & cations: calcium (hardness), magnesium, sodium, potassium, iron, aluminium, copper, manganese, zinc

- Ammonium (NH₄⁺)

- Arsenic and other elemental impurities

- Turbidity (NTU) and colour (Pt/Co scale)

- Disinfectant residues: free/total chlorine, ozone, hydrogen peroxide

Microbiological Tests Available

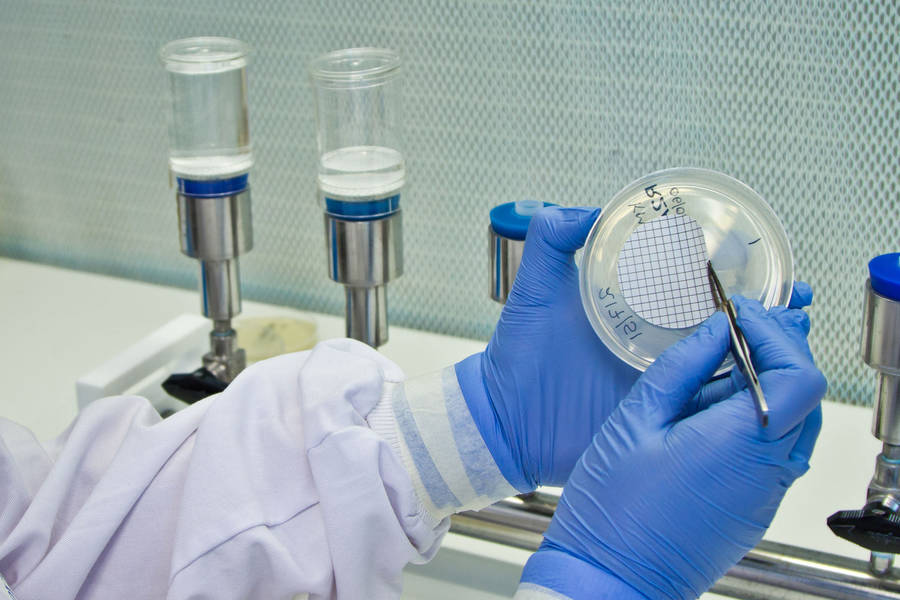

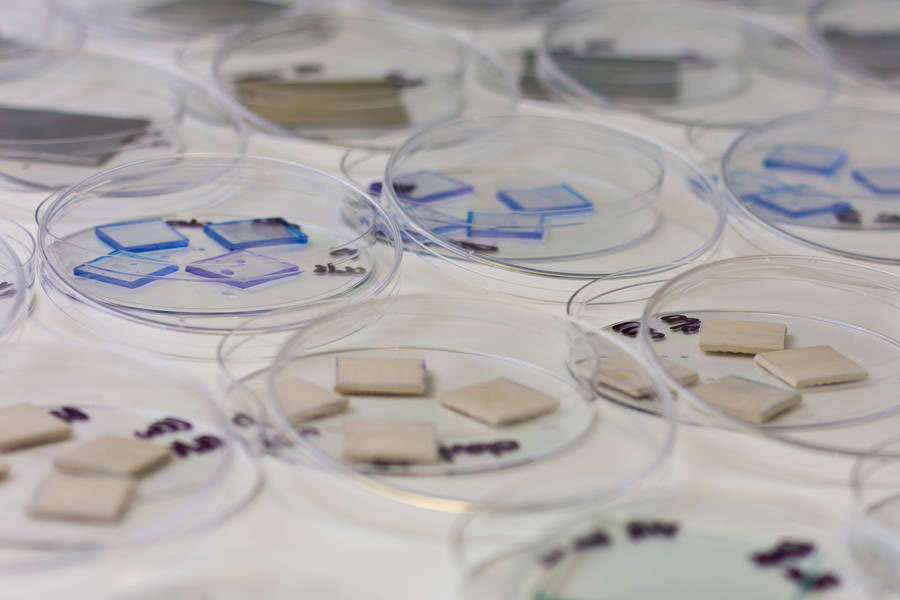

- Total viable count (TVC) via membrane filtration

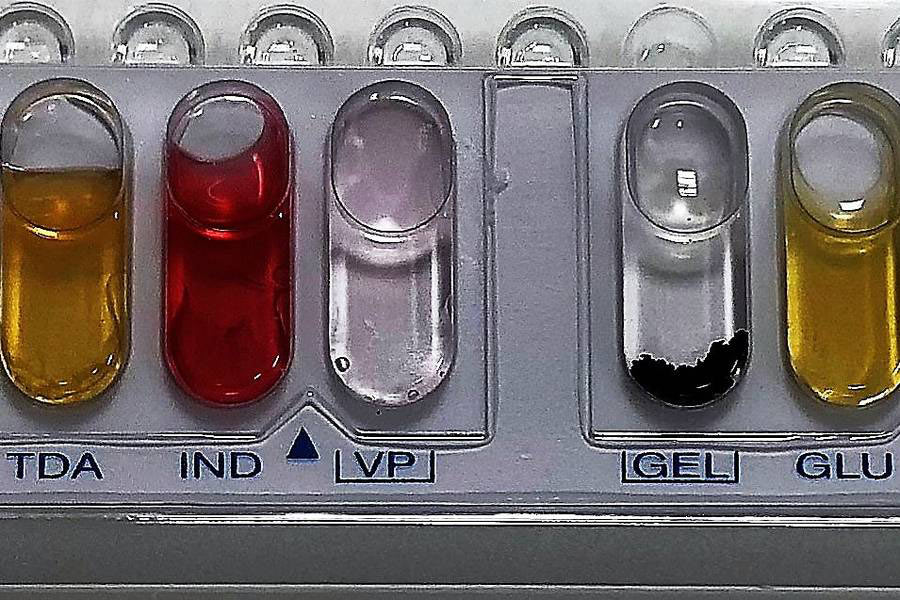

- Absence of specified organisms (e.g., E. coli, P. aeruginosa)

- Endotoxin testing where required

Rapid On-Site Testing Options

Honeyman also provides colorimetric kits for on-site monitoring of parameters like chlorine, hardness, phosphate, ammonia, and iron, ideal for real-time decisions and troubleshooting.

Why Choose Honeyman?

- MHRA-approved, cGMP laboratories with over 30 years of experience

- Onsite GMP-trained samplers and validated cold-chain transport

- Audit-ready reports with clear interpretation, trending, and CAPA recommendations

- Integrated support from Honeyman Water for engineering, design, and lifecycle optimisation

Custom Limit Testing to Meet Your Needs

Our testing is aligned with your URS and quality risk assessments, referencing pharmacopoeial and WHO/EU standards when applicable. If a required parameter isn't listed, we can develop and validate bespoke methods tailored to your process.

Contact Us

Our Customers: