Cleaning Validation Samples

Cleaning contamination identification

Cleaning Validation Sample Testing

Ensuring Effective Cleaning Validation in Pharmaceutical Manufacturing

Cleaning validation is a critical GMP requirement. Regulators expect robust evidence that manufacturing equipment is effectively cleaned between product campaigns, preventing cross-contamination and ensuring patient safety. A key part of this validation is the sampling and testing of equipment surfaces and rinse waters.

Honeyman Laboratories provides a complete cleaning validation support service — from onsite sampling by trained GMP personnel to MHRA-approved laboratory analysis and interpretation of results. By integrating with the wider Honeyman Group expertise, we ensure that your cleaning validation programme meets the expectations of the MHRA, FDA, EMA, PIC/S and WHO.

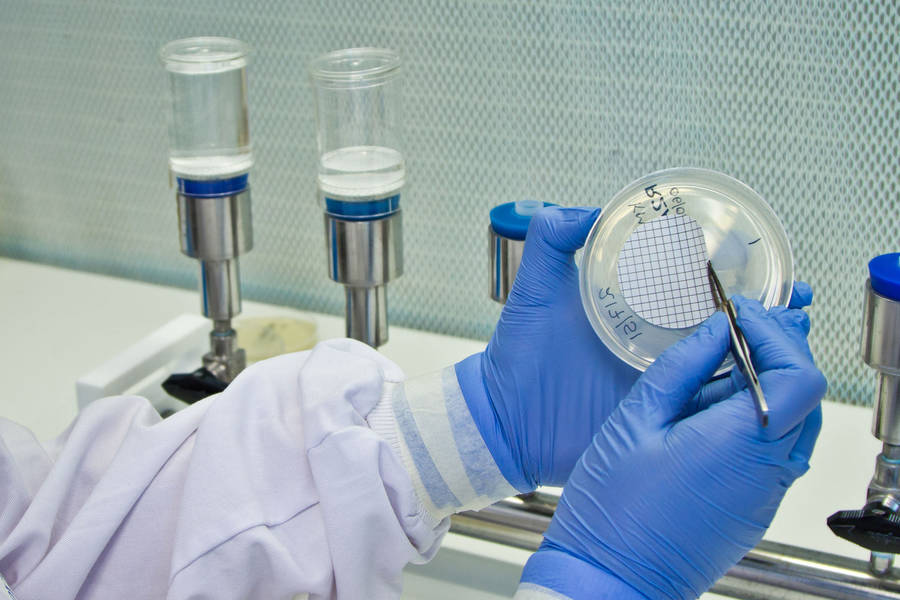

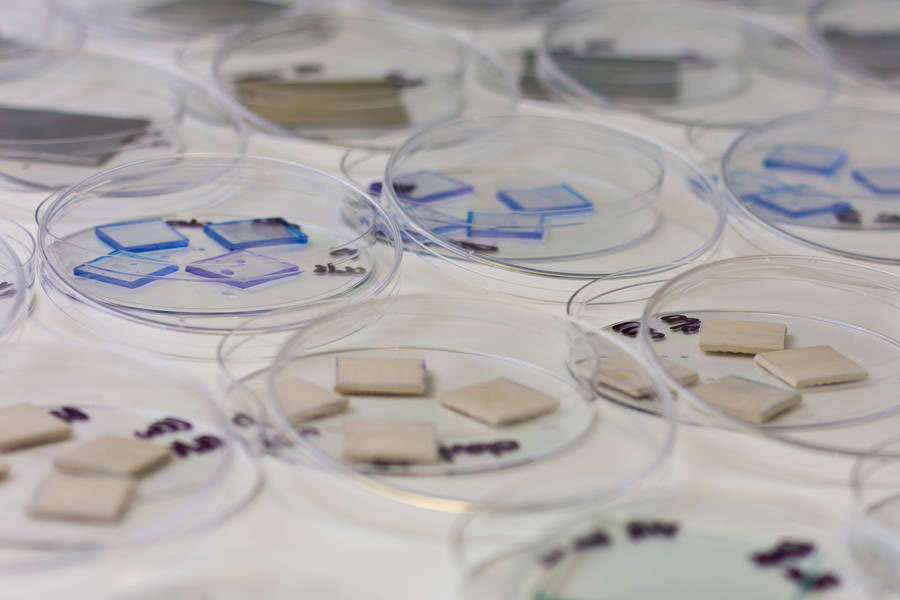

Sampling Methods We Support

We provide both direct and indirect sampling approaches in line with global regulatory guidance (EU GMP Annex 15, FDA Process Validation Guidance, PIC/S PI 006):

All samples are taken under strict GMP conditions, transported under validated chain of custody, and analysed in our own laboratories to ensure data integrity and regulatory compliance.

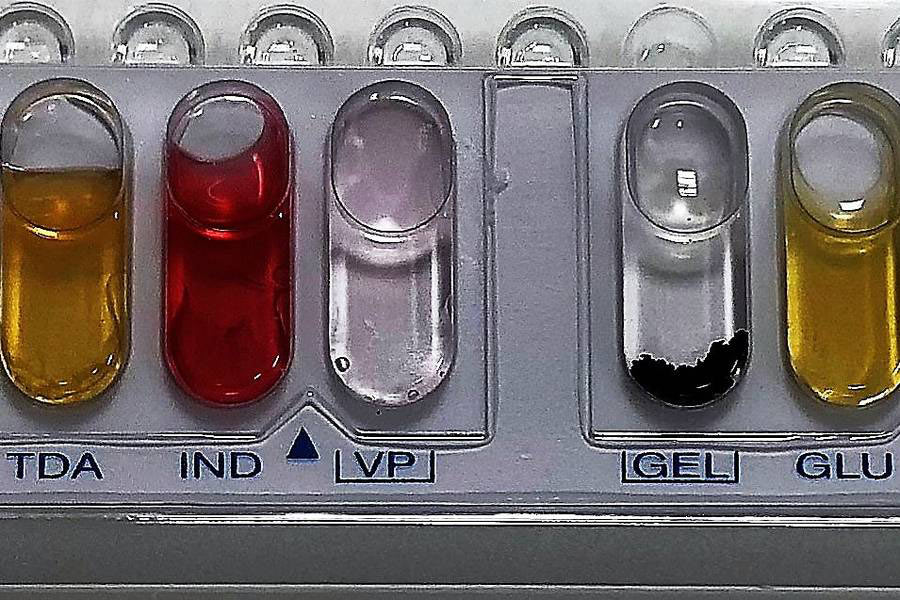

Analytical Methods

Our laboratories perform a wide range of compendial and bespoke analyses for cleaning validation samples, including:

Where required, Honeyman develops and validates bespoke analytical methods specific to the product or cleaning agent being assessed.

Acceptance Criteria and Recovery Studies

Cleaning validation acceptance limits are generally based on toxicological or dose-based calculations, supported by visual cleanliness as per EMA/ISPE guidance. Common approaches include:

Honeyman performs recovery studies to confirm that swabbing and rinse sampling methods can reliably recover known amounts of residue from representative surfaces, ensuring that negative results are valid and defensible.

Why Choose Honeyman?

Lifecycle Support

Cleaning validation is not a one-off activity. Honeyman provides ongoing support for periodic revalidation, trending of TOC and HPLC results over time, review of acceptance limits, and remedial action planning in the event of non-compliance.

With Honeyman, you gain a partner that provides complete lifecycle support, ensuring your cleaning validation programme remains effective, compliant and inspection-ready.

Partner With Honeyman

Cleaning validation failures are one of the most common causes of regulatory findings. Partner with Honeyman Laboratories for trusted GMP sampling, laboratory testing and documentation that keeps your products — and your patients — safe.

Our Customers: