Disinfectant Efficacy Testing

4 Key Changes Proposed in Disinfectant Efficacy Testing by Annex 1

At Honeyman, our aim is keep our clients up to date with all the current regulatory requirements as well as providing an impartial view on future changes that might affect you.

As we communicated earlier in February via our e-news bulletin, there are a significant amount of proposed changes to Annex 1 of the EU GMP.

In this edition we highlight the EU GMP proposed changes to Annex 1 which include a new Disinfection section has been added to Section 5 Premises.

The proposed revision to Annex 1 describes that medicinal product manufacturers require a contamination control strategy to be in place to minimise the risk of contamination events from microbial sources. A key control measure at many steps in the manufacturing process for microbial contamination is disinfection of personnel, equipment, and facilities.

The four key changes regarding disinfection are summarised below;

- Disinfectants should be shown to be effective for the duration of their use taking into consideration appropriate contact time and manner in and surfaces on which they are utilised.

- Monitoring should be undertaken regularly in order to show the effectiveness of the disinfection program to detect the development of resistant and or spore forming strains.

- Disinfectants should be monitored for microbial contamination.

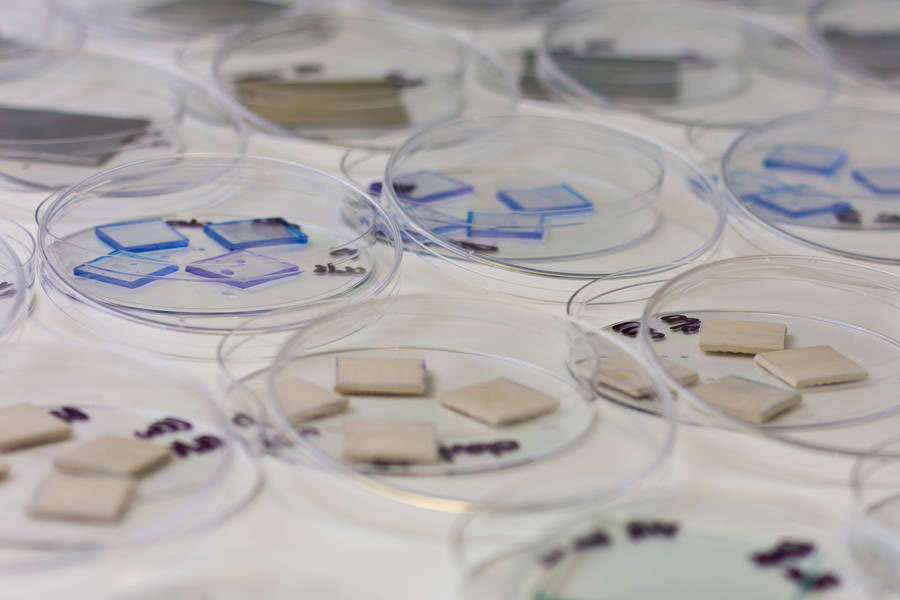

- Disinfectants should be should to be effective when used on the specific facilities, equipment and processes they are used in.

At the steps in the process which rely on the use of manual disinfection techniques, it is vital to understand how effective the disinfectant is on micro flora found in that step within the facility.

Examples of items that may need to be disinfected include

- shoes

- gloved, ungloved hands

- equipment

- machinery

- wrapped filling components

- facility surfaces

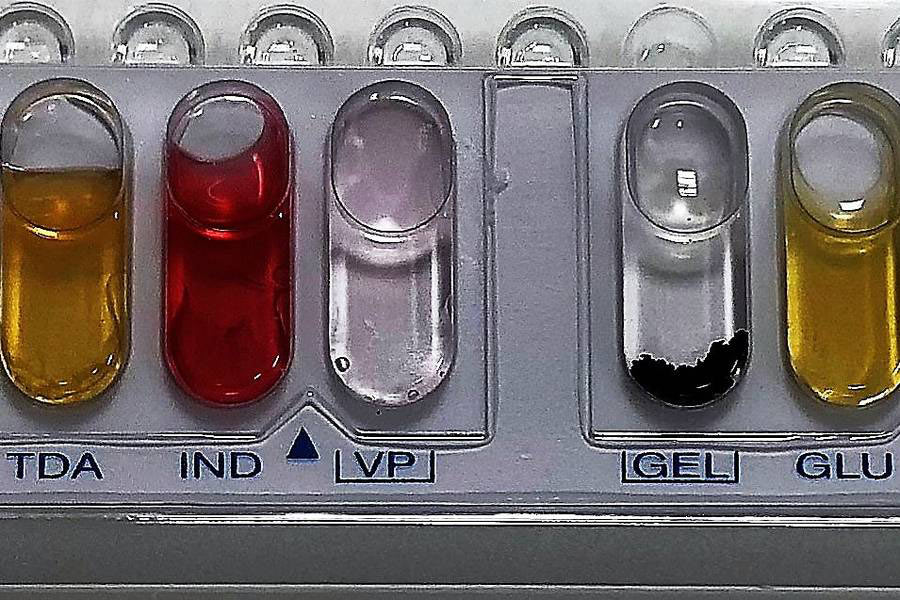

This means that the bioburden for the step needs to be understood and the actual in use disinfectant should be challenged with the environmental isolates recovered from the facility to demonstrate the efficacy of the disinfection process.

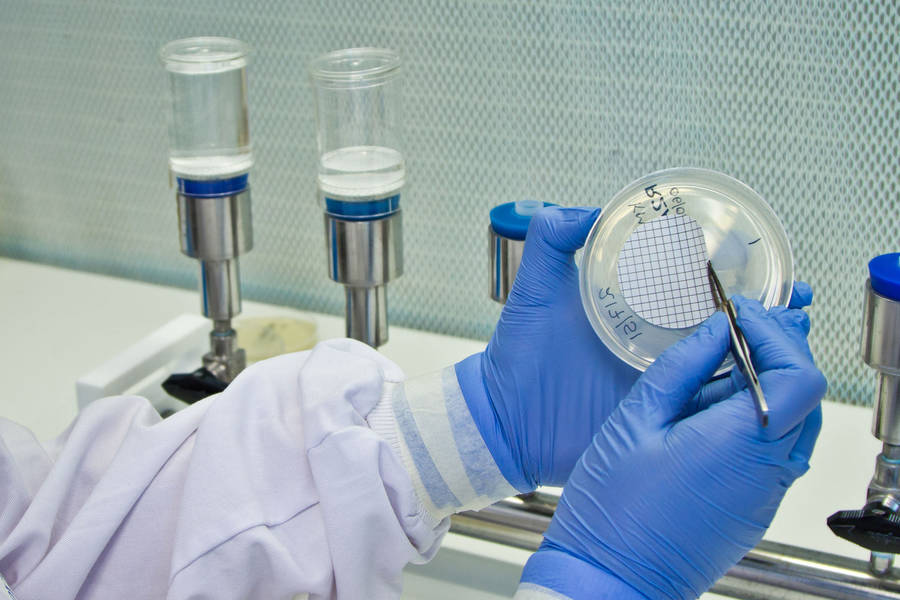

At the Honeyman Group we have worked with many clients to verify that the in-use disinfectant was effective and suitable for use the process. We have experience of the standard suspension and surface tests defined in the ISO standards. On many occasions have been able to develop bespoke methodology which is representative of the in house cleaning and disinfection regime used by the client in their facility.

For further information regarding Disinfection Efficacy Testing, see our dedicated DET page on the Laboratory site or contact a member of the Honeyman Group Laboratories team to discuss your specific requirements.

Email enquiries@honeymangroup.com and phone +44(0) 1833690101

Our Customers: