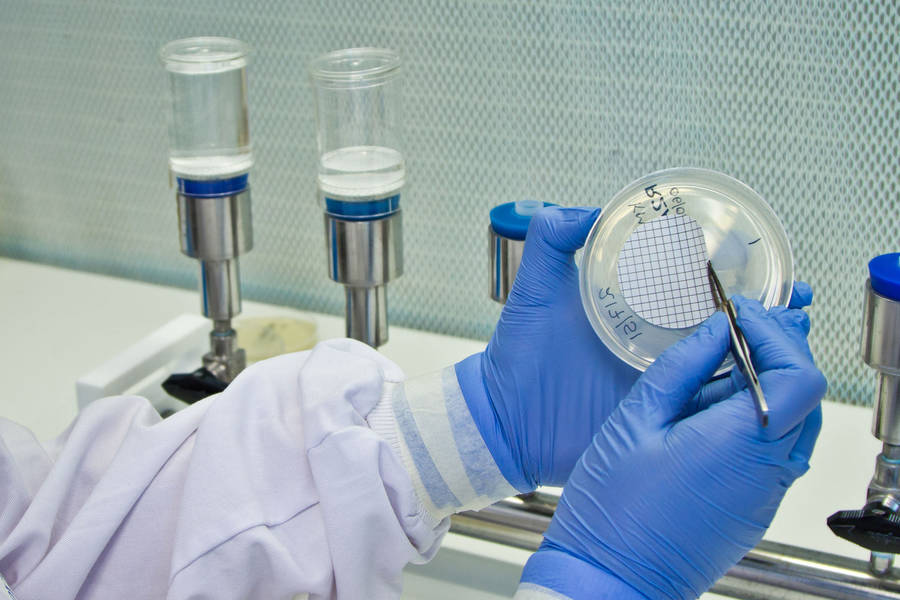

Product and Raw Material Testing

Physical and chemical quality assessment

What is Finished Product Analysis and Material Testing?

Finished Product Analysis and Material Testing is the physical and chemical quality assessment of pharmaceutical items or materials. These parameters are assessed and performed for raw material testing prior to manufacturing and for finished product testing on a batch basis prior to product release as part of routine QC checks.

Why do we do it?

It is a regulatory requirement defined within every pharmacopoeia that products, both sterile and non-sterile, must be assessed for their chemical quality. As such, each product must have an associated, validated method for chemical analysis which is performed routinely on every batch. This provides confidence on the quality of every batch manufactured, to ensure the safety of the end user.

We typically perform analysis in accordance with the monographs detailed in the following pharmacopoeias:

European Pharmacopoeia (Ph. Eur.)

United States Pharmacopoeia (USP)

British Pharmacopoeia (BP)

Japanese Pharmacopoeia (JP)

In house methods

How do we assure compliance?

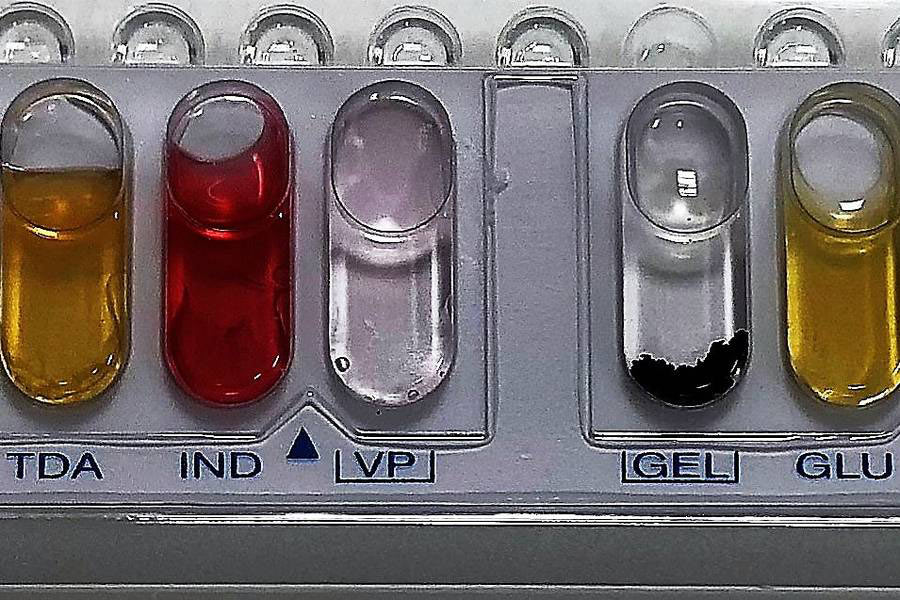

The complement of testing required differs from product to product and is highly variable. Below are examples of common QC release tests performed at Honeyman:

- Physical Parameters for solid dosage forms (Average weight, friability, disintegration etc)

- Dissolution

- Content Uniformity

- Identification by HPLC, FTIR and UV Spectrophotometry

- Product Assay by HPLC and UV

- Related Substances by HPLC

- Karl Fischer – water content

- Titrations (Compleximetric, Acid-Base, Oxidation Reduction and Non-Aqueous)

- Autotitrations (Potentiometric)

We are also capable of performing Client product specific testing, contact us now for more information on our capabilities.

Our Customers: