Disintegration Testing

Capsules, tablets and enteric coated tablets

What is Disintegration Testing?

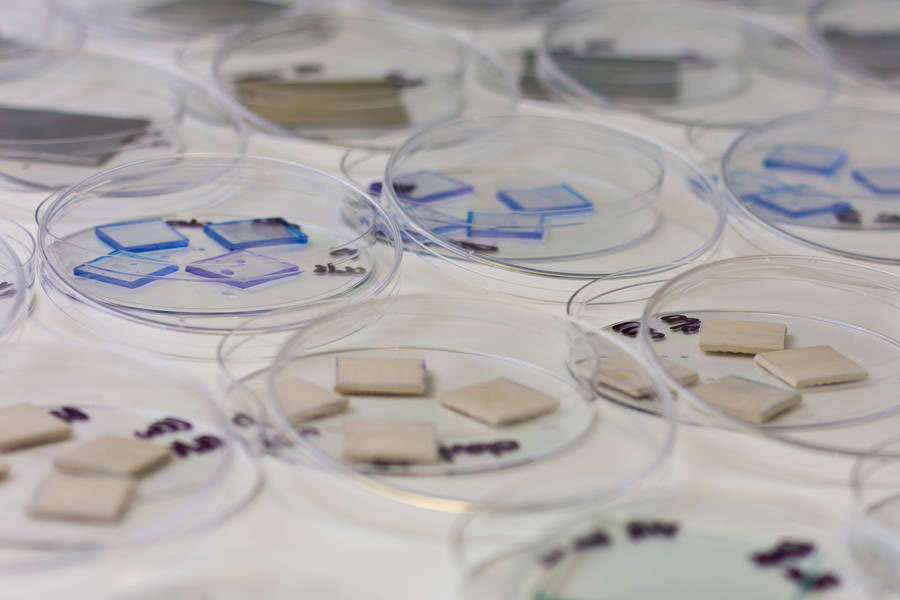

Prior to the dissolution of a solid dosage form, it should be established that the tablet or capsule must first disintegrate into smaller parts. Disintegration testing accurately measures, under standard conditions, the ability of a sample to break into smaller particles. This testing is typically performed on tablets, capsules and enteric coated tablets.

Why do we do it?

Like dissolution testing, Disintegration is often a pharmacopoeial testing requirement for the vast majority of solid dosage forms. It provides critical safety data on drug bioavailability in the body without having to utilise in vivo methods. Establishing consistency and uniformity across all batches using this method is a critical quality control step. Each pharmacopoeia specifies its own standard conditions for the performance of disintegration testing.

How can we help assure compliance?

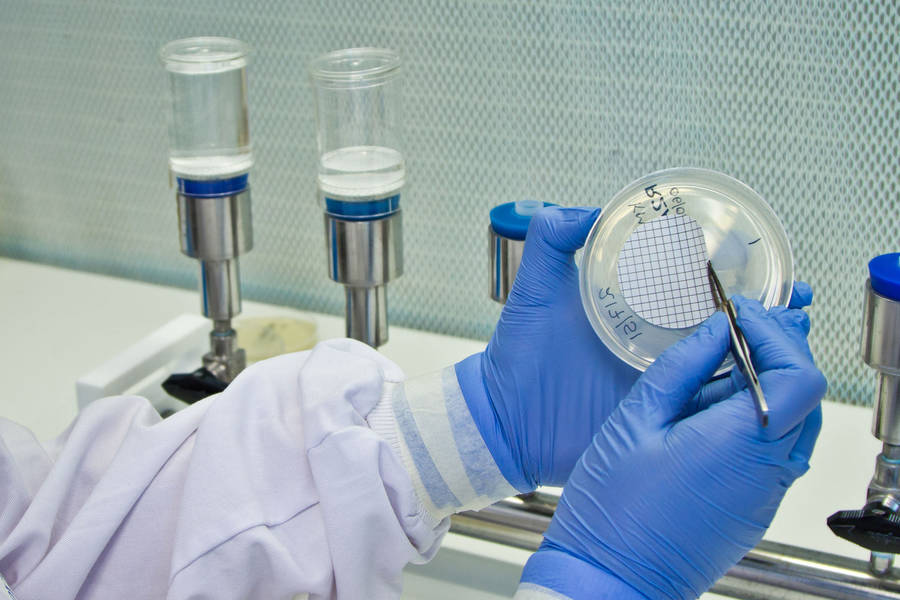

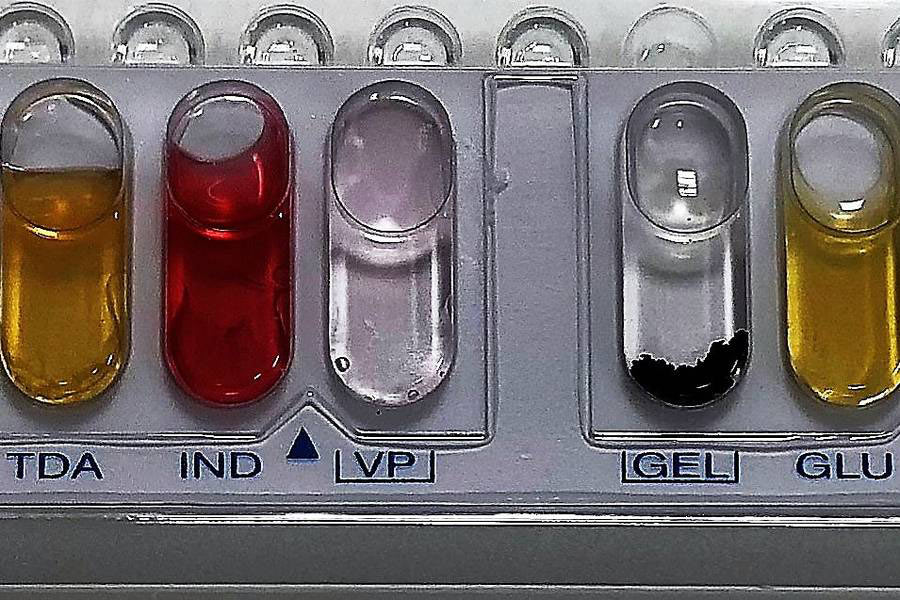

Disintegration testing must yield consistent results as it is a direct assessment of product performance. The typical method involves the preparation of “simulated gastric fluid” which is similar to dissolution media. The samples are agitated within the fluid at 37°C under mechanical stress applied by a plunger of known dimensions in an attempt to replicate in-vivo conditions. Methodology can vary depending on the apparatus, Honeyman are capable of performing Disintegration testing in accordance with the following pharmacopoeias:

- European Pharmacopoeia (Ph. Eur.)

- United States Pharmacopoeia (USP)

- Japanese Pharmacopoeia (JP)

Our Customers: