D-value Verification

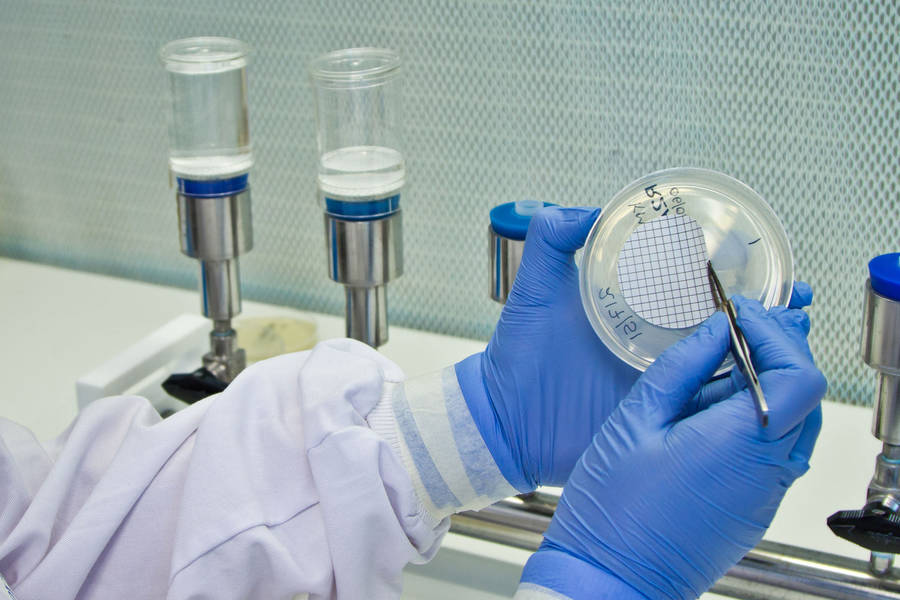

Custom inoculation & product assessment.

D-value Verification

Honeyman is one of the only independent contract laboratories with the capability to perform D-Value and Z-Value analysis and other associated thermal studies by direct inoculation of product or equipment using Biological Indicator Organisms (BI's).

What is D-value Verification?

The D-value refers to time taken at a given temperature to reduce the population of exposed microorganisms by 90% or achieve a 1-log reduction. The z-value is the temperature increase required to reduce the d-value by one log. For example, D-value of 2.5 minutes at 121°C equates to a 90% reduction in viable bacteria in 2.5 minutes at those conditions. If the temperature is increased to 131°C and the D-value at 131 is 0.25 minutes – the Z-value can be said to be 10°C. This parameter is of particular important during sterilisation validation and Fo controlled processes and low temperature sterilisations. D-values are stated by the manufacturer on the Biological indicator but often require verification for a higher degree of accuracy and process specificity.

Why do we do it?

Thorough understanding of the properties of your BI is critical to sterility assurance. The Pharmacopoeias and ISO11138 discuss the importance of D-value verification to ensure the accuracy of a stated manufacturer D-value. Our experts recommend that if a biological indicator bioburden approach is used for sterilisation validation, D-value verification should be performed.

How?

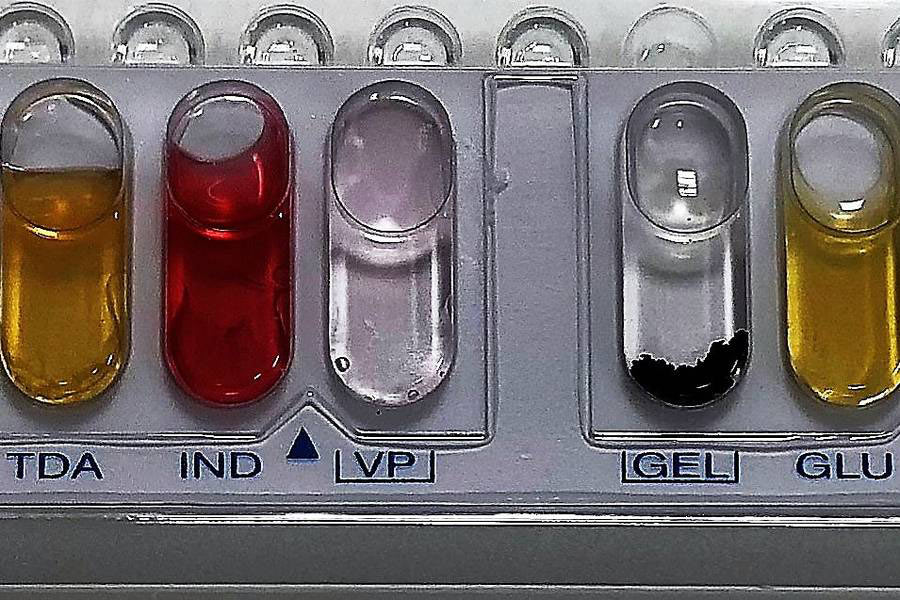

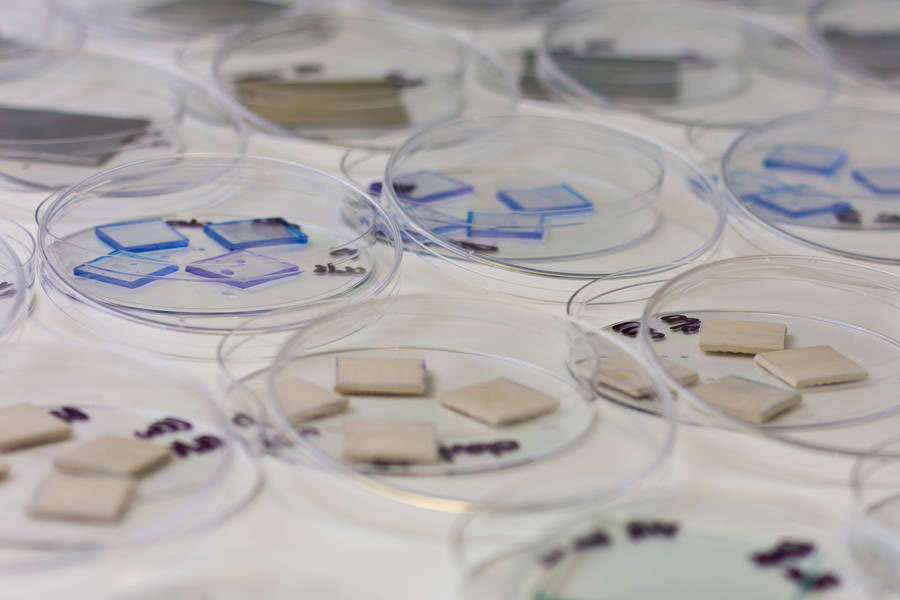

D-value verification is performed in a specialist autoclave named a Biological Indicator Evaluation Resistometer (BIER) Vessel. In essence, this is an autoclave that accurately delivers a calibrated and pre-determined level of lethality, typically steam sterilisation at 121°C. This allows us to assess the effect of the stable sterilisation conditions on biological indicator resistance with the heat up and cool down phase having minimal contribution to the Fo.

The BI’s are exposed for defined time points and interpreted via fractional analysis to assess the log reduction achieved for exposure time. This process allows us to verify manufacturers stated D-value with a higher degree of accuracy and specificity. Accurately assessing the D-value gives a higher degree of assurance when calculating the Fo of sterilisation and how that correlates with achieving the desired Sterility Assurance Level (SAL).

For further information and advice on Biological Indicators please browse our knowledge hub below, or contact us about your analytical testing requirements.

Our Customers: